Manufacturing Profile

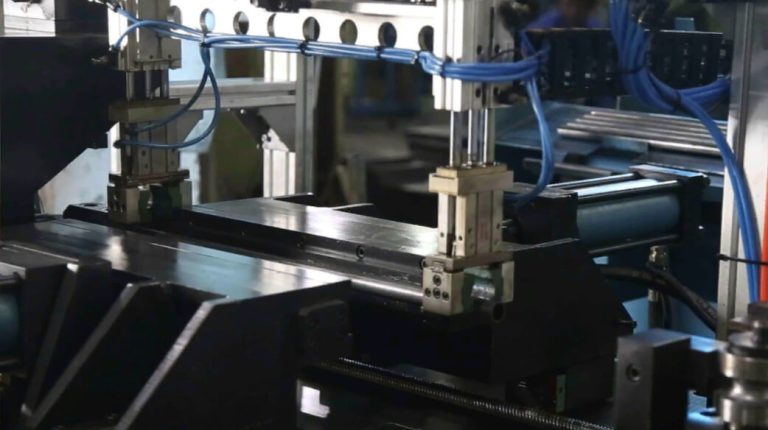

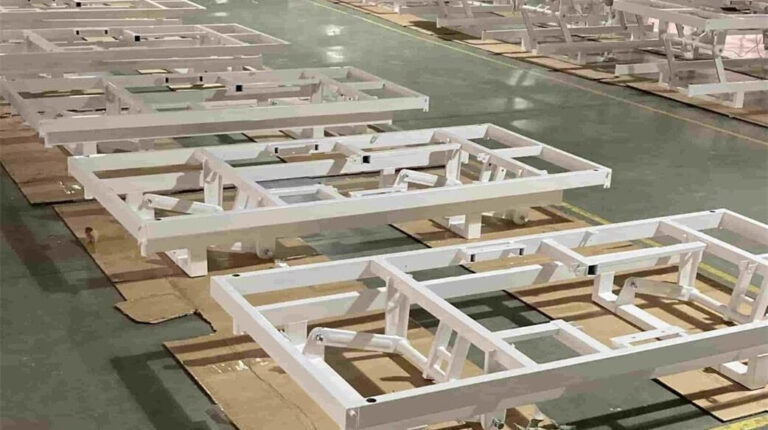

Sun Medical has established our own complete production chain and facilities: tooling→metal processing→welding→surface treating→injection molding→sewing→final assembly, thus guaranteeing all-process production management, all-process quality control, timely delivery and competitive price.

40000㎡

40000㎡ factory area

350+

350+ skilled workers

200+

200+ models

Mainly 4 product families:

power mobility, manual mobility, bathroom safety, nursing equipment

Assembly line quantity:

2 assembly lines for power mobility items —

electric wheelchair, mobility scooter;

4 assembly lines for manual mobility items —

wheelchair, rollator, knee walker, walker/cane/crutch;

3 assembly lines for bathroom safety & nursing equipment —

bath seat, commode chair, toilet safety aids, nursing bed, transfer chair, accompany chair.

Manufacturing Capability

We maintain very strong manufacturing capability, so we can always meet our customers' rising demands and deliver quality goods timely.

Besides, we keep investing more facilities and staffs to guarantee 30% spare capacity anytime.

With rapid growth, we are also planning to build another branch factory for further expansion.

Here is our production capacity for some of the main products:

electric wheelchair & mobility scooter — 9,000pcs/month;

manual wheelchair — 60,000pcs/month;

rollator & knee walker — 35,000pcs/month;

bath seat & commode — 40,000pcs/month;

transfer chair — 6,000pcs/month;

nursing bed — 3,000pcs/month.